High temperature resistant

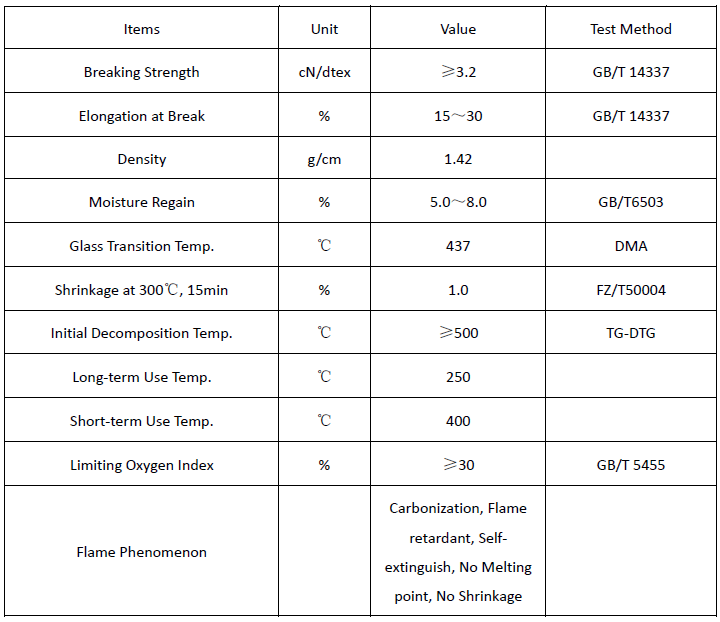

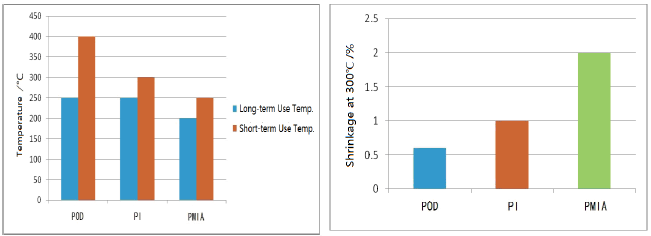

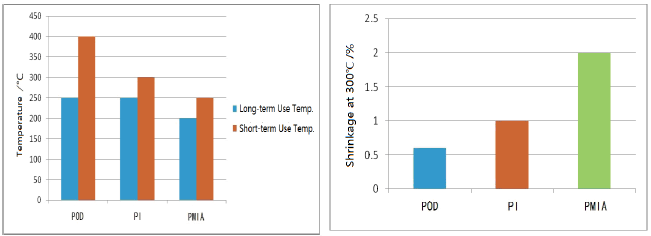

POD has excellent heat-resisting performance, its thermal decomposition temperature can reach up to 530℃, applied to the working condition of 250℃. No matter in hot water or in the hot air, POD has excellent dimensional stability. Its boiling water shrinkage is less than 0.5%, and its heat shrinkage rate under 250℃ and 300℃ is 0.6% and 1% respectively. Due to the high glass transition temperature(437℃), even if the temperature is higher than 400℃, POD can still keep good dimensional stability and do not shrink.

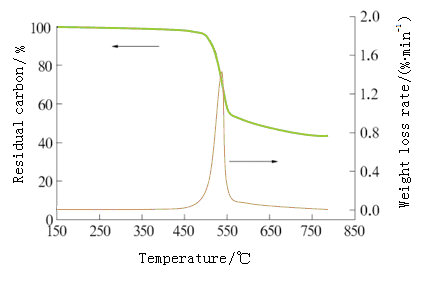

TG-DTG Graphic of POD

Flame resistant

POD contains flame retardant function group in its molecular chain. It can realize flame resistant with no flame retardant and has a permanent flame retardancy. POD’s limiting oxygen index can reach up to 32%. It doesn’t melt during burning and shrink. It has a higher residual carbon after combustion.

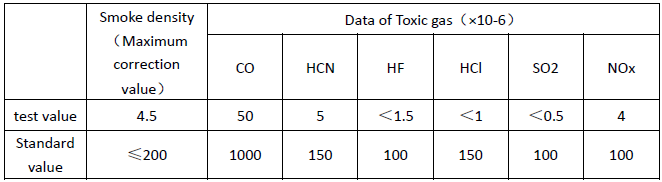

POD releases gas smoke with a small density and a low toxicity when it is burning. From the test report of POD’s smoke density and toxicity reported by civil aviation administration of China testing center, the density and toxicity of POD’s smoke are less than the civil aviation standards. And in the fiber blending with other smoke it can improve the combustion status of the fabric.

Smoke Density and Toxic of POD

The damaged length can be improved by POD when fabric is burning. The vertical combustion damaged length of POD fabric is around 25mm. With its excellent skeleton, it can obviously improve the performance in the fiber blending with flame retardant viscose, acrylic chlorofibre, wool and so on. In addition, POD releases less heat in the combustion process.

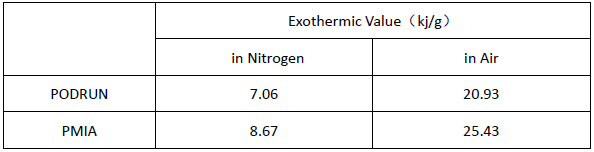

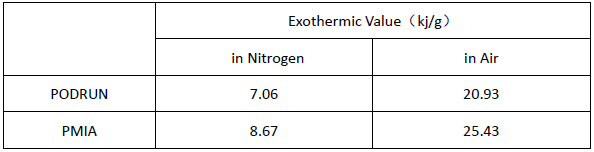

Exothermic Value of PODRUN and Nomex

Electrical insulating

Slightly

Easy dyeing

POD is easy dyeing and its cost is low. It uses disperse dyes to dye, whose dyeing technology can be reference to polyester fiber. And its dyeing rate can reach more than 90%. POD can use a variety of staining forms, including loose hair dyed, yarn bobbin dyeing and dye. Meanwhile, it has a strong adaptability.

Comfortable feeling

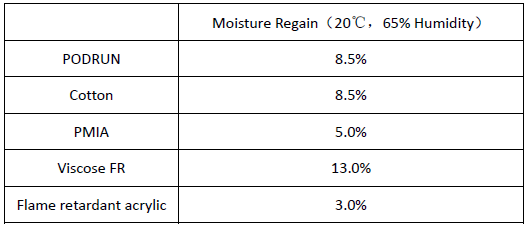

The state of aggregation structure of POD is given priority to with amorphous structure. It has an amazing softness. Adding wool and aramid system can effectively improve the fabric handle. POD’s moisture regain under the standard condition can be up to 8.5%, having the same comfortable feeling with cotton and viscose. Adding POD into wool and aramid system can obviously improve the fabric‘s handle and comfort, which can be worn directly.

Moisture Regain of Some Fiber

>Application Field

Individual protection

As the flame retardant high temperature resistant fiber which has independent intellectual property rights, POD fills the domestic blank. Its chromaticity, shrinkage resistance and comfortability are adapted to the development trends of protective fabrics and market demands, injecting new vitality for protective areas. As a flame retardant fiber, POD is unique among similar products due to its excellent anti-shrinkage, cotton handle and comfort.

Flame retardant uniforms

POD can be used in the production of combat fatigues in special operations forces, air resistance to the Netherlands and tanks, ships uniform and relevant underwear, etc.

Industry protective clothing

POD has excellent properties of thermal protection, hygroscopicity and air permeability. It can not only effectively prevent the invasion of thermal radiation, but also promote the evaporation of sweat and ventilation, promoting the distribution of body heat and helping the people who wears it active more flexible to cope with various emergencies. POD can be used to produce the industry protective clothing of firefighter uniforms, before-furnace suits, electrowelding clothes, arc protection coveralls and oil overalls, etc.

Industry uniforms

POD has a high flame retardant grade and a good synergistic flame retardant effect with wool. POD can be added into wool system to produce the industry uniforms of public security, taxation and judicial departments. It not only has the flame retardant function, but also can improve the comfort and handle of the fabric.

High temperature insulation

POD has higher heat resistance and lower heat shrink with better heat insulation performance. It can be used in the production of protective clothing insulation blanket, aluminum high temperature conveyor belt, roller, all kinds of fire gloves, fire blankets, fire prevention materials, etc.

Environmental protection

POD has excellent heat resistance, good chemical resistance and well spinnability. It can be processed into non- woven fabrics which are widely used in industrial high temperature flue gas filtration of cement, steel, asphalt and metallurgy, etc.

Temperature Resistance Advantage of POD